It's one of those jobs that everybody knows, but few of us really think much much about. Tailors get all the credit for the style of clothing and quite naturally the merchants made all of the money, but most of the hard work come from the weavers. I first remember hearing about the weavers of Europe as a child, but mostly related to being put out of work as a result of the industrial revolution, the death of the "cottage industry" (followed by the Luddites). Obviously these industrious workers had a long run before that time, so I figured it was time to explore the intricate world of the weaver (sorry, was just imagining that last bit read as an intro to a PBS special or something).

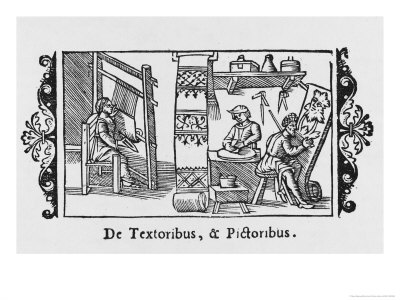

It's one of those jobs that everybody knows, but few of us really think much much about. Tailors get all the credit for the style of clothing and quite naturally the merchants made all of the money, but most of the hard work come from the weavers. I first remember hearing about the weavers of Europe as a child, but mostly related to being put out of work as a result of the industrial revolution, the death of the "cottage industry" (followed by the Luddites). Obviously these industrious workers had a long run before that time, so I figured it was time to explore the intricate world of the weaver (sorry, was just imagining that last bit read as an intro to a PBS special or something). Weaving was done at home in Medieval Europe. Weavers were often men, with the women of the house spinning the thread needed and helping with the finishing of the material. Cloths were primarily produced in wool, linen and nettlecloth (for the poor). Initially, the resultant products were sold at local faires. As the trades became more organized (forming guilds) in larger settlements, merchants became middle-men for the weavers. By the 13th Century, these merchants were both supplying the wool for the weaving as well as buying back the finished product, thereby dominating cloth production and controlling wages. Following the plague (1346), land prices dropped (increasing pasture land for sheep) and these new landlords moved weavers to those cottages (aka factories) in the countryside.

Weaving itself is simply the interlacing of warp (longitudinal lines) and weft (lateral lines). Warp threads are held taught, acting as the ground. A weft thread (a pick) is guided through the warp to make the pattern. Those patterns, oh god, a whole different post. The basic process of weaving on a loom is to first use the loom's heddles to make a space (a shed) for the pick to pass (shedding), then move the pick through the space (picking), and finally pushing the weft snugly up against the previous pick (beating-up or battening) using the reed (which looks like a comb). The pick may be shedded by hand or with a shuttle. Shuttles are normally pointed on both ends and the the filling yarn is mounted onto a quill, which is then mounted onto the shuttle. A selvage is formed at both edges of the fabric to prevent raveling (which surprisingly means unraveling), by looping the thread back into the weave. The selvage may or may not maintain the pattern of the rest of the cloth. Yes, this is the simplified version.

Weaving itself is simply the interlacing of warp (longitudinal lines) and weft (lateral lines). Warp threads are held taught, acting as the ground. A weft thread (a pick) is guided through the warp to make the pattern. Those patterns, oh god, a whole different post. The basic process of weaving on a loom is to first use the loom's heddles to make a space (a shed) for the pick to pass (shedding), then move the pick through the space (picking), and finally pushing the weft snugly up against the previous pick (beating-up or battening) using the reed (which looks like a comb). The pick may be shedded by hand or with a shuttle. Shuttles are normally pointed on both ends and the the filling yarn is mounted onto a quill, which is then mounted onto the shuttle. A selvage is formed at both edges of the fabric to prevent raveling (which surprisingly means unraveling), by looping the thread back into the weave. The selvage may or may not maintain the pattern of the rest of the cloth. Yes, this is the simplified version.  Loom styles have changed significantly through the course of history. With a Back Strap Loom (Southeast Asia and Americas still today), one end is tied to a fixed point and the other end loops around your back. Leaning back puts tension on the system, so you need to lean forward to create the shed. Because the weaver is tied to the machine, this limits the width of the cloth to arm's reach. The Warp-Weighted Loom is a vertical design which uses the aforementioned weights, suspended from a tree or beam, to keep tension on the warp. This may have been the earliest loom design, but it continued to see use in ancient Greece and spread throughout Europe. The Simple Frame Loom is effective, but generally only for smaller sized areas of cloth, as the weave is limited by the dimensions of the frame. The Horizontal Loom (11thC) was a big development, allowing continuous lengths of cloth to be produced by collecting the completed cloth in a roll in front of the weaver as new weft unrolls from the far end of the loom. Foot pedals were also used to lift the alternate sets of weft to create the shed. The Hand Loom (12thC) is a simple machine in which the heddles are all fixed, so that by raising the shaft, half of the warp lifts to create the shed. Similarly, lowering the shaft lowers the same half of the warp to create the shed (on the other side). Free-Standing Looms and Pit Looms are much larger endeavors. These looms both have multiple harnesses and foot-pedals (treadles) which allow a greater variety of patterns at a greater rate of speed. Other looms were developed between those discussed, some for specific types of products (narrow bands, tapestries, and so on), but these seem like a good overview for our present area (and level, sheesh) of interest.

Loom styles have changed significantly through the course of history. With a Back Strap Loom (Southeast Asia and Americas still today), one end is tied to a fixed point and the other end loops around your back. Leaning back puts tension on the system, so you need to lean forward to create the shed. Because the weaver is tied to the machine, this limits the width of the cloth to arm's reach. The Warp-Weighted Loom is a vertical design which uses the aforementioned weights, suspended from a tree or beam, to keep tension on the warp. This may have been the earliest loom design, but it continued to see use in ancient Greece and spread throughout Europe. The Simple Frame Loom is effective, but generally only for smaller sized areas of cloth, as the weave is limited by the dimensions of the frame. The Horizontal Loom (11thC) was a big development, allowing continuous lengths of cloth to be produced by collecting the completed cloth in a roll in front of the weaver as new weft unrolls from the far end of the loom. Foot pedals were also used to lift the alternate sets of weft to create the shed. The Hand Loom (12thC) is a simple machine in which the heddles are all fixed, so that by raising the shaft, half of the warp lifts to create the shed. Similarly, lowering the shaft lowers the same half of the warp to create the shed (on the other side). Free-Standing Looms and Pit Looms are much larger endeavors. These looms both have multiple harnesses and foot-pedals (treadles) which allow a greater variety of patterns at a greater rate of speed. Other looms were developed between those discussed, some for specific types of products (narrow bands, tapestries, and so on), but these seem like a good overview for our present area (and level, sheesh) of interest. The last area I want to touch on is spinning, which is the production of the yarn used in weaving (plus I always heard about it in fairy tales). The basic idea is to draw out the individual strands, twist them together for strength, and then wind them onto a spindle (or bobbin) for later use. Unfortunately, the spinning wheel wasn't available until the High Middle Ages, leaving us with the spindle and distaff to do the work (so much for the fairy tales). The distaff was basically a stick for holding the mass of material to be spun. This was placed under the arm or tucked in the girdle to leave the left hand free to draw out the strands. The spindle is also basically a stick with a split in the top to start the twist. It is held in the right hand and collects the twisted yarn. The twirling of the spindle gives the yarn its twist, before being wrapped onto the finished mass. Spinning was such a common (and useful) practice that many unmarried women did it in their free time, giving rise to the term spinster.

The last area I want to touch on is spinning, which is the production of the yarn used in weaving (plus I always heard about it in fairy tales). The basic idea is to draw out the individual strands, twist them together for strength, and then wind them onto a spindle (or bobbin) for later use. Unfortunately, the spinning wheel wasn't available until the High Middle Ages, leaving us with the spindle and distaff to do the work (so much for the fairy tales). The distaff was basically a stick for holding the mass of material to be spun. This was placed under the arm or tucked in the girdle to leave the left hand free to draw out the strands. The spindle is also basically a stick with a split in the top to start the twist. It is held in the right hand and collects the twisted yarn. The twirling of the spindle gives the yarn its twist, before being wrapped onto the finished mass. Spinning was such a common (and useful) practice that many unmarried women did it in their free time, giving rise to the term spinster. Goodness, I really had no idea what I was getting into when I started all of this. Even the simple mechanics of this require some fair three-dimensional thinking. It makes me boggle a bit to start thinking of changing colors and patterns in the weave. It's no wonder that guilds existed to share the skills and regulate the trade of the medieval weaver. However weaving was not done solely by the professional. Small communities might have a large frame loom for shared use. Many of the poor could not afford to buy their own cloth, but looms were also very expensive. They might instead take their spun wool to a nearby weaver, much like a farmer taking their grain to the mill. The weaving of cloth was obviously an important job in every community. I hope our little investigation today adds a member to a community you create some day.

http://en.wikipedia.org/wiki/Weaving#Medieval_Europe

http://en.wikipedia.org/wiki/Loom

http://www.history.uk.com/clothing/weaving-on-off-looms/

http://scholar.chem.nyu.edu/tekpages/loom.html

simple frame loom demo - http://www.youtube.com/watch?v=61jdqH0Ji_4

http://www.cd3wd.com/cd3wd_40/vita/handloom/en/handloom.htm

http://en.wikipedia.org/wiki/Hand_spinning

Bosnian woman hand spinning wool - http://www.youtube.com/watch?v=1R03D_QWVdc

No comments:

Post a Comment