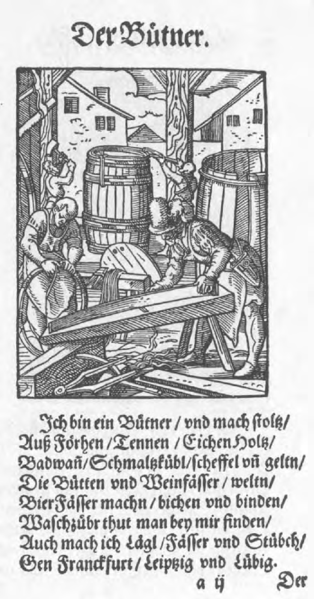

A cooper is a craftsman who works with wooden staved vessels, including:

casks, barrels, buckets, pipes, butter churns, tubs, butts, etc; bound

together with hoops of wood or metal. Fully closed barrels are known as far back as the Iron Age (800-900 BCE). Today the tradition is carried on

primarily in service to the wine or spirit making industries.

Traditionally the skills and tools of the cooper were handed down for

generations. The skills of the cooper were prized in every medieval community.

A cooper is a craftsman who works with wooden staved vessels, including:

casks, barrels, buckets, pipes, butter churns, tubs, butts, etc; bound

together with hoops of wood or metal. Fully closed barrels are known as far back as the Iron Age (800-900 BCE). Today the tradition is carried on

primarily in service to the wine or spirit making industries.

Traditionally the skills and tools of the cooper were handed down for

generations. The skills of the cooper were prized in every medieval community. There are four basic divisions within the trade. "Dry" or "slack" coopers made containers used to transport dry goods such as cereals, nails, and vegetables. The "dry-tight" cooper made casks designed to keep moisture out (like for flour), usually from oak. "White" coopers made straight (unbent) staved containers like washtubs, buckets and butter churns, that would hold water, but not allow for shipping of liquids (often of cedar or pine). The "wet" or "tight" cooper made casks for long-term storage and transportation of liquids that could even be under pressure, as with beer.

The work of the cooper begins long before the assembly of the vessel. To gather the correct materials for the work, first a tree must be selected to produce the proper staves. Straight unblemished oak trees (for wet or tight work) about five feet in circumference work best. This wood should have no knots The tree is then cut into boards and the boards cut down into staves. These rough staves then need to be dried. Plane the outside of the staves to make them smooth. The ends of the staves need to be tapered to fit and the inside area hollowed out and flattened.

The work of the cooper begins long before the assembly of the vessel. To gather the correct materials for the work, first a tree must be selected to produce the proper staves. Straight unblemished oak trees (for wet or tight work) about five feet in circumference work best. This wood should have no knots The tree is then cut into boards and the boards cut down into staves. These rough staves then need to be dried. Plane the outside of the staves to make them smooth. The ends of the staves need to be tapered to fit and the inside area hollowed out and flattened. A few final steps before we're ready for use. First, the tops of the side staves need to be notched evenly to receive the lid. Now the lid should be fabricated and fitted into place. Then the outside of the barrel should be planed and sanded to smoothness and any bung or additional detail work completed. Then, simply fill with water and test for tightness. Simple, right?

great overall reference - http://www.rootsweb.ancestry.com/~flbbm/heritage/cooper/barrelmaking.htm

medieval images - http://larsdatter.com/coopers.htm

wiki - http://en.wikipedia.org/wiki/Cooper_%28profession%29

colonial - http://www.history.org/almanack/life/trades/tradecoo.cfm

for wine barrel detailed construction - http://www.beekmanwine.com/prevtopah.htm

No comments:

Post a Comment